Redline Markup on Electrical Plans

By knowing how to do Levven takeoffs and redlines, you can:

- Maximize materials savings

- Give field crews plans they can follow to wire and trim homes

- Know what Levven products are needed to complete the installation

- Make potential future servicing easier by keeping controllers accessible

Add Wire Markup on Electrical Plan

Two-conductor wire (2C) is represented by a 1-point dashed line.

Three-conductor wire (3C) is represented by a 3-point dashed line.

Home Runs

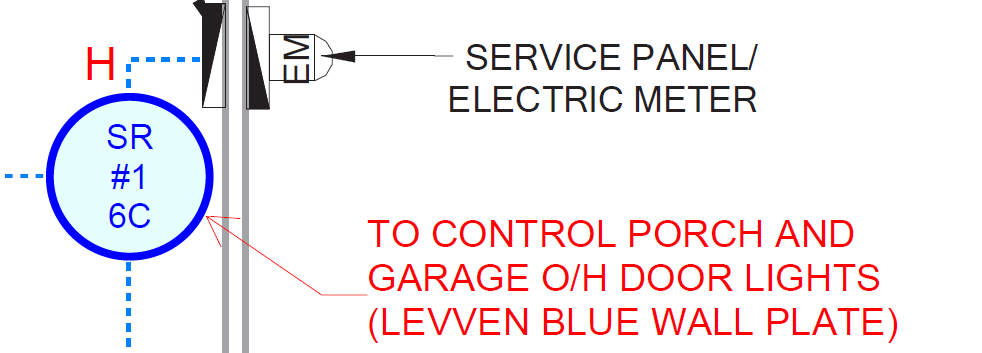

The home run is 2C wire directly from the electrical panel to a fixture or controller. Mark it with an "H" on the redline.

Blue Pairing Plate

The "Blue Pairing Plate" is a GPC10 installed behind the Levven Blue Pairing Plate. It's typically located near the electrical panel to control the light in that room.

The Blue Pairing Plate holds one GPC10 controller and is installed in a single-gang box.

Add a home run from the electrical panel to the Blue Pairing Plate, and then wire to the switched load and continue with power to the next controller.

- See Installing the Blue Pairing Plate for more details.

Box Fill

Verify box fill requirements with your local electrical code.

Each single-output Levven controller counts as two conductors for box fill. Typically, each junction box may have maximum 12 conductors - 10C from wire, and one single-output controller.

Constant Power

Each controller needs constant power for proper operation.

When there is a second controller after the first controller's load, and the first controller is switching multiple fixtures, use 3C wire.

Wire Between Junction Boxes

Add 2C and 3C wire to provide constant power to each controller, and connect controllers with their switched loads.

Aim for short wire runs and avoid areas where there may be a significant amount of mechanical equipment

Smoke Detectors

Smoke detector junction boxes may be used for controllers switching other loads (such as a ceiling fan).

Use 2C wire to the first smoke detector and use 3C wire between smoke detectors.

- Box fill is 9C + one single-output controller. Beyond this, use an extension ring.

Add Labels for Junction Boxes

Adding labels for each junction box which contains a controller tells crews:

- Which kind of junction box to use.

- Which controller is installed in the junction box.

- How many conductors enter and exit the junction box.

For each junction box containing a controller, add a label like the one below:

Label Color

Color | Controller Type | Controller Part Numbers |

Blue | Blue Pairing Plate | GPC10 |

Green | Single-output | GPC10, GPC20, GPDT15, CP1-4 |

Box Type

ID Code | Description | Capacity | Equivalent Part Numbers |

DP | Deep plastic box, 25 cubic inch | One controller only | US: Carlon BH25HP Canada: Nutec WOCT |

DPWE | Deep plastic box, 25 cubic inch, with 2-inch extension ring | One or two controllers | US: Carlon BH25HP and 2-inch box extender Canada: Nutec WOCT and 2-inch box extender |

4MBR | 4” x 4” box with device mud ring | One or two controllers | US: Carlon B432ARR-UPC and 1-Gang Single-Device Flat Square Cover Canada: Nutec WRD and 1-Gang Single-Device Flat Square Cover |

SRP | Single-gang receptacle box | One controller only | US: Carlon B122A Canada: Nutec WSW |

Controller Number

The controller number is an easy reference to between the controllers listed in your takeoff spreadsheet and their locations on the redline.

Count Conductors

Count the conductors entering and exiting the junction box using the formula below:

Conductor count = (count of 2C wires × 2) + (count of 3C wires × 3)

Calculate this count for each junction box containing a controller.

Add Takeoff Details to Plan

Use the takeoff spreadsheet to generate the count of each SKU you will need to order. Add this, along with a legend, as the first page of the redline.

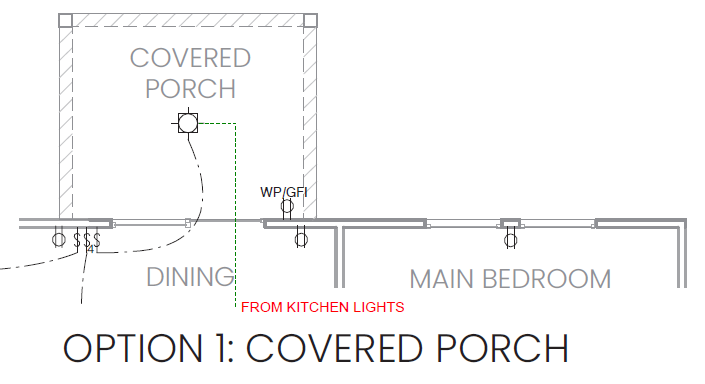

Builder Option Packages

When redlining for option packages, add the wiring markup as it differs for that option. Note on the electrical plan where the wiring entering/leaving the options section goes to.